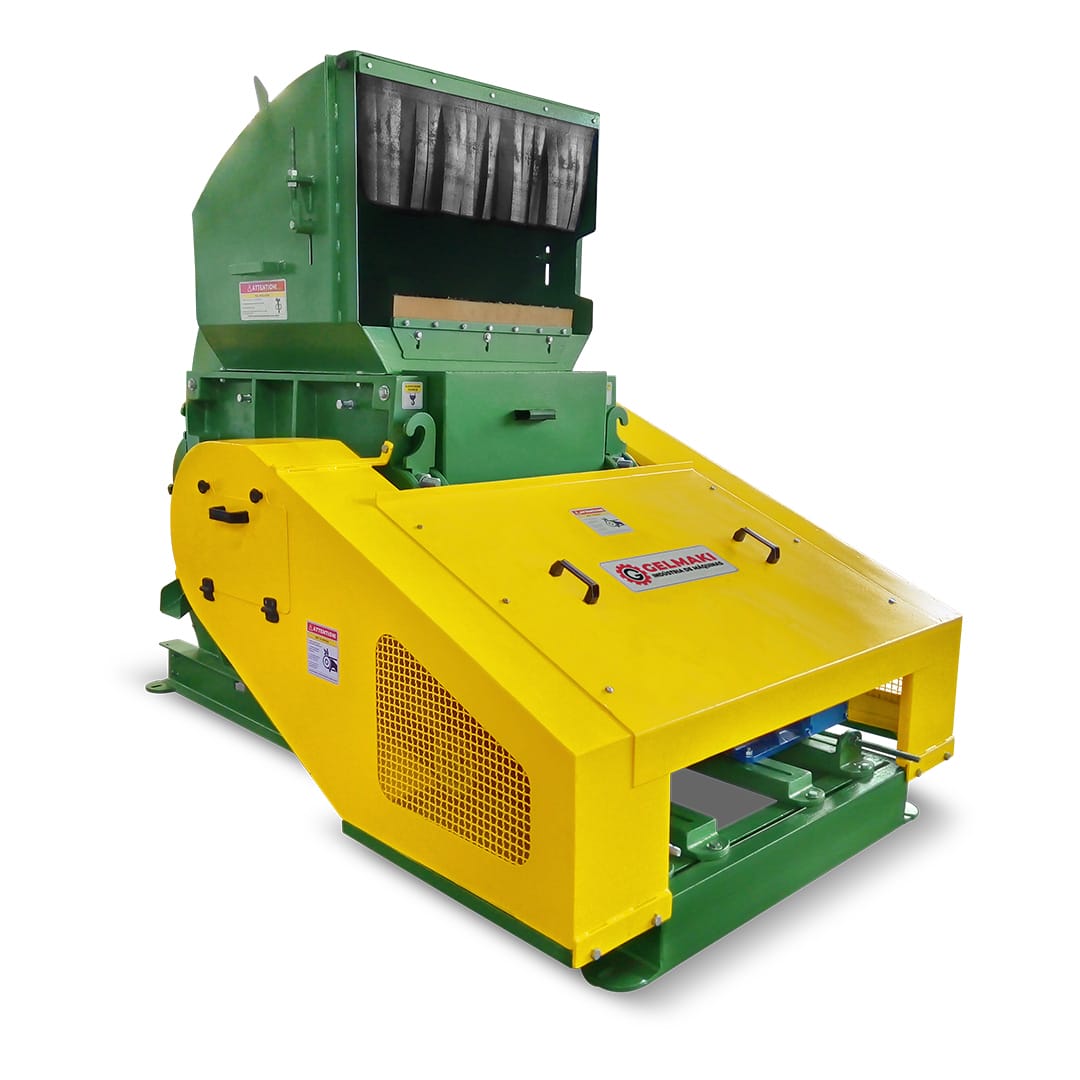

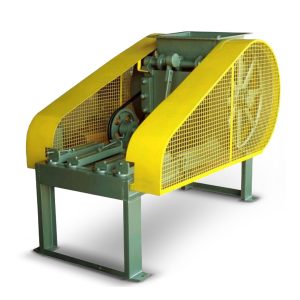

Disintegrator DIG – 400

- Production: 05 to 18 Ton/h

- Cylinder Width: 400 mm

- Cylinder Diameter: 400/300 mm

- Rotation: 210/530 RPM

- Power: 7.5 + 10 HP – 4 Poles – 1740 to 1760 RPM

- Weight: 1,000 Kg

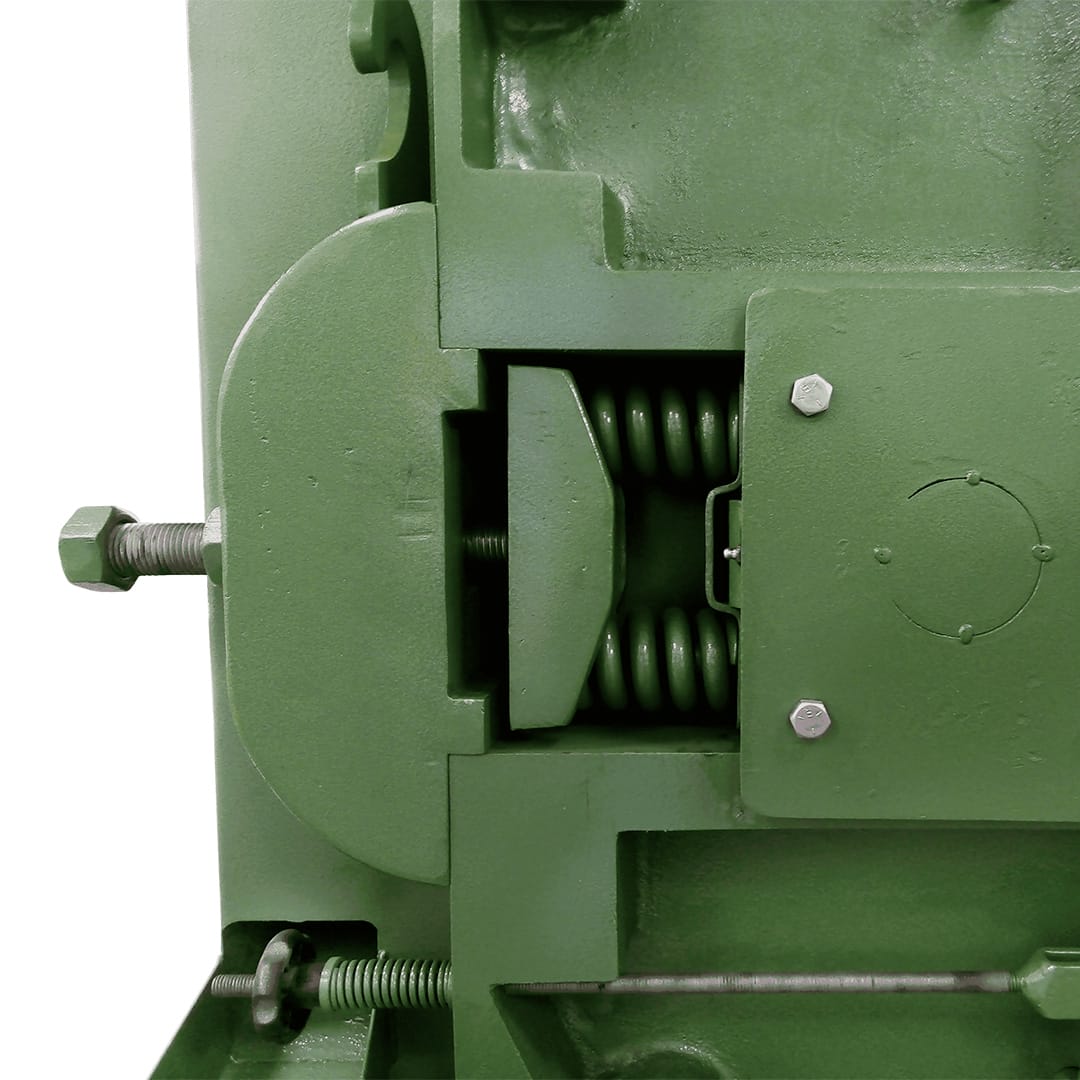

- Interchangeable parts for easy access and exchange.

- Safety device against shocks and mechanical impacts.

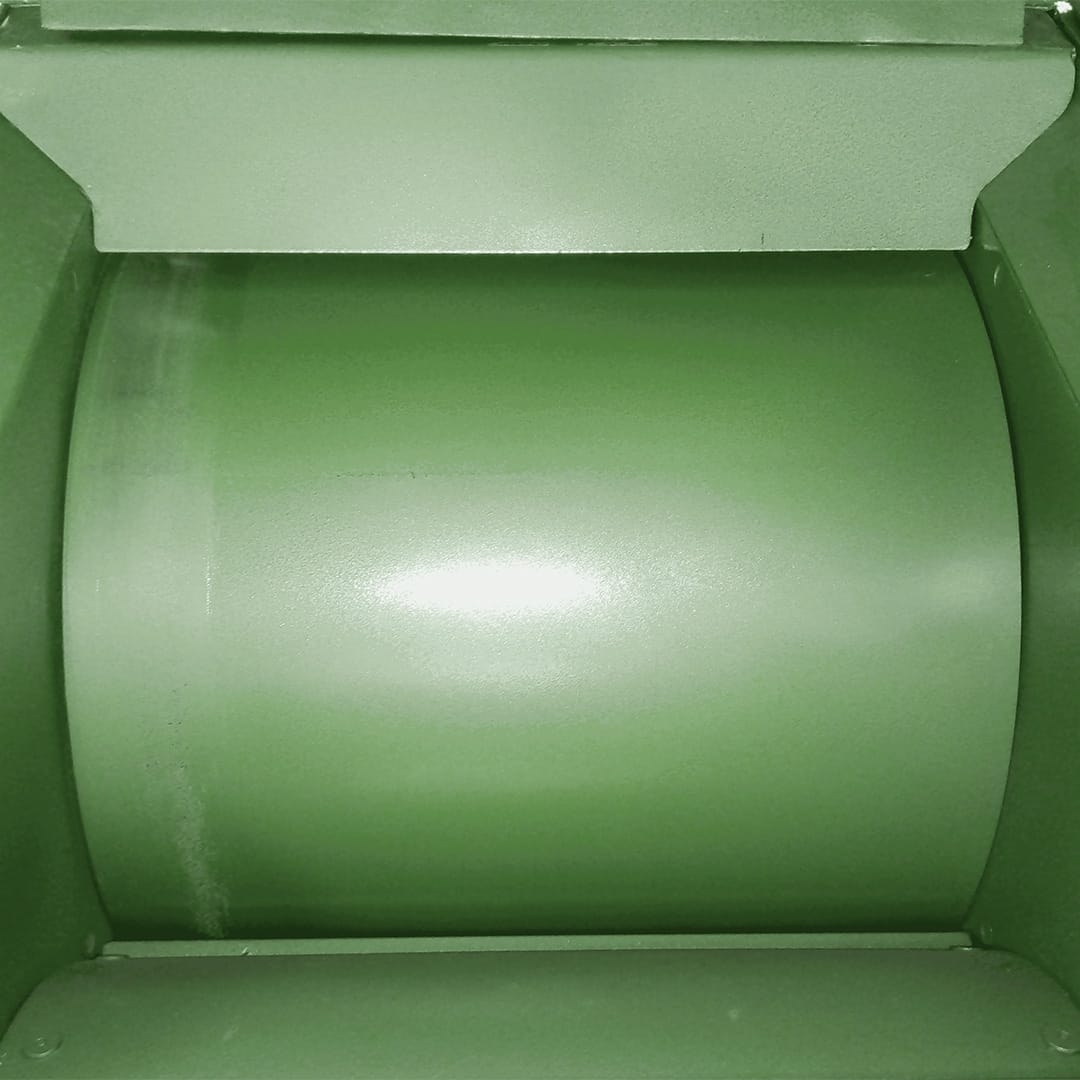

- Cylinder made of high quality material, resistant and durable.

Description

The Disintegrator, model DIG – 400, is the first piece of equipment in the clay preparation line and is responsible for carrying out the first steps of crushing the clay, whether it is dry or semi-moist, leaving the material pre-laminated for the production sequence, increasing the quality of the ceramic mass and bricks.

It has two cylinders, one of 400 mm that works at low speed, maintaining constant feeding, and another cylinder of 300 mm with metal crossbars that rotate at high speed to break up the dry lumps that hinder the absorption of water and the action of the Mixer and/or Homogenizer in the sequence.

The best and most resistant materials on the market are used for its manufacture, which guarantee the resistance and durability of the equipment. Its parts, in addition to being highly resistant and durable, have an interchangeable system, ensuring the possibility of easy and quick replacement.

It also has a safety device against mechanical impacts caused by foreign bodies that may come with the clay/material. Thus, preventing damage to the equipment or possible accidents.