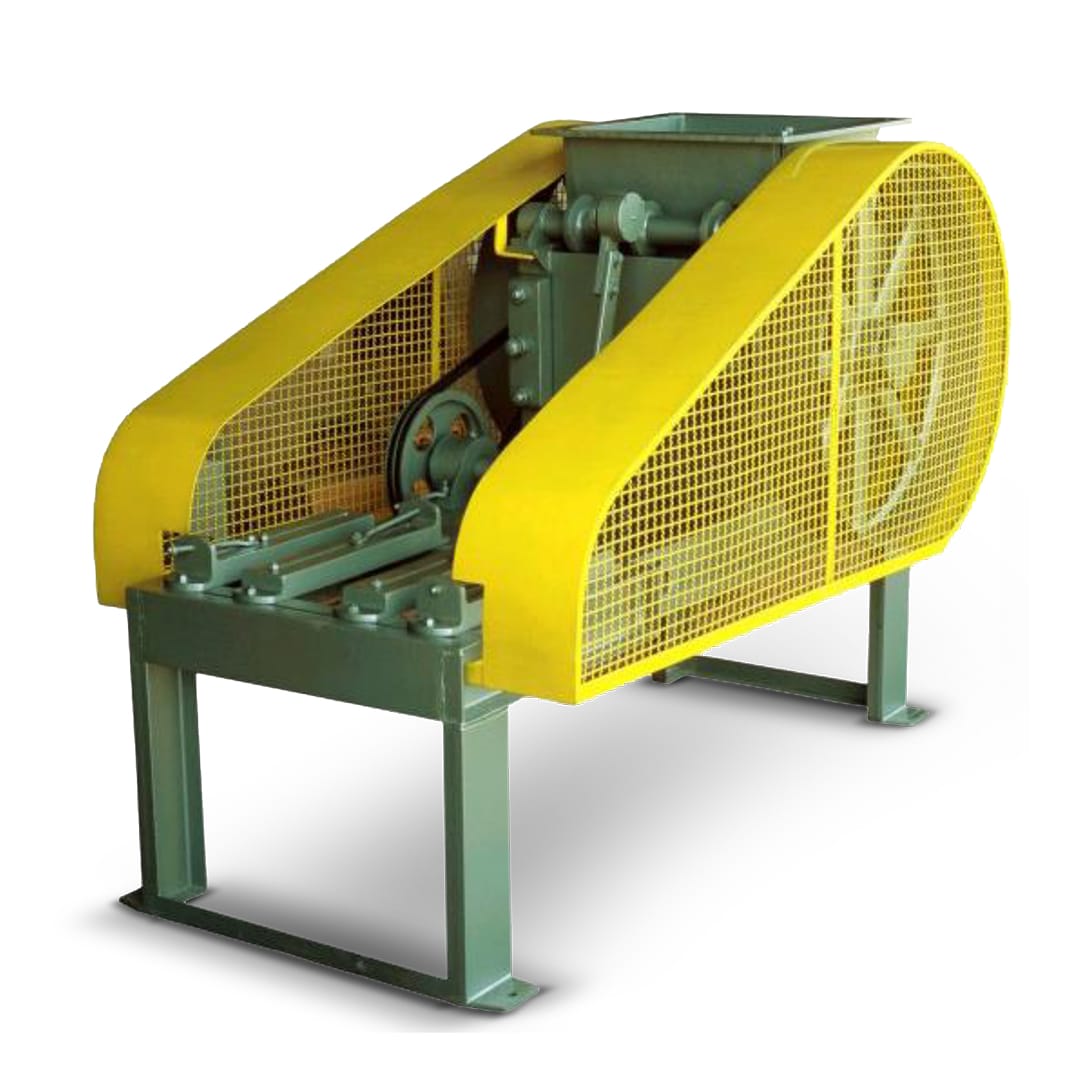

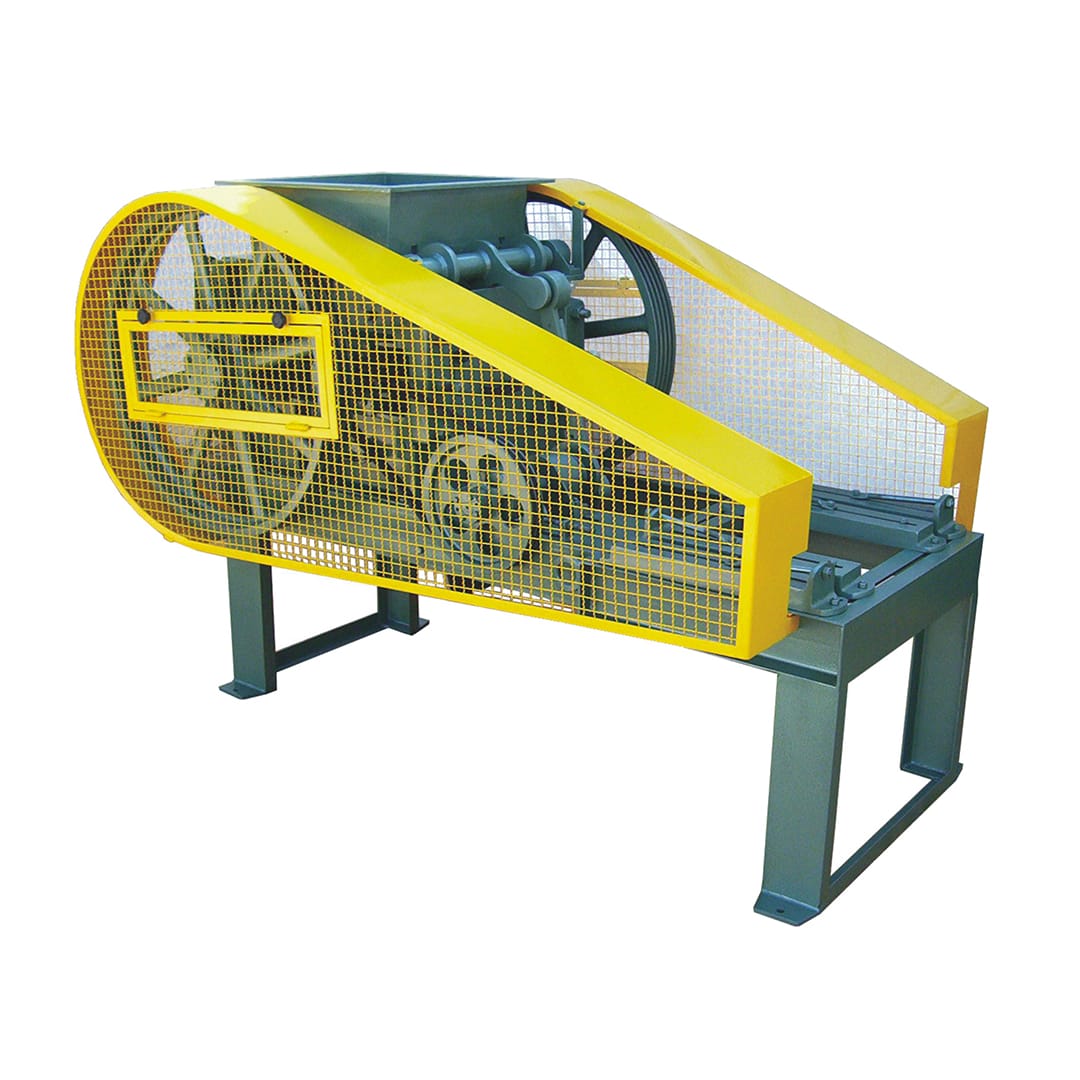

Rolling Mill LIG – 350

- Production: 05 to 12 Ton/h

- Cylinders Width: 400 mm

- Cylinders Diameter: 350 mm

- Cylinders Rotation: 210/250 RPM

- Power: 7,5 + 10 HP / 4 Poles / 1740 + 1760 RPM

- Weight: 1,500 Kg

- Adaptable to your production needs.

- Interchangeable parts for easy access for possible changes.

- Rod made with high quality, resistant and durable material.

- Clay distribution system over the cylinders, avoiding localized wear.

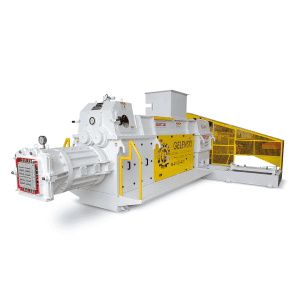

Description

Complementing the mixer’s work, the LIG – 350 was developed to ensure better homogeneity of the ceramic mass. It evenly distributes water in the ceramic mass, this process ensures that the clay is more homogeneous, increasing the quality of the final product.

Its lamination system is highly efficient, using several technologies to ensure that your material has the best quality. It also has a clay distribution system that prevents localized wear and increases the useful life of the cylinders!

It was designed with durability and long-lasting operation in mind, which is why it is produced using resistant and high-quality materials, capable of maintaining good operation for several years of production. In addition to being highly resistant and durable, its parts have an interchangeable system, ensuring the possibility of easy and quick replacement.

It also has multiple safety systems, such as fuses against shocks and mechanical impacts caused by foreign bodies in the ceramic mass. This prevents irreversible damage to the equipment and possible accidents with people nearby.