Tunnel Kiln

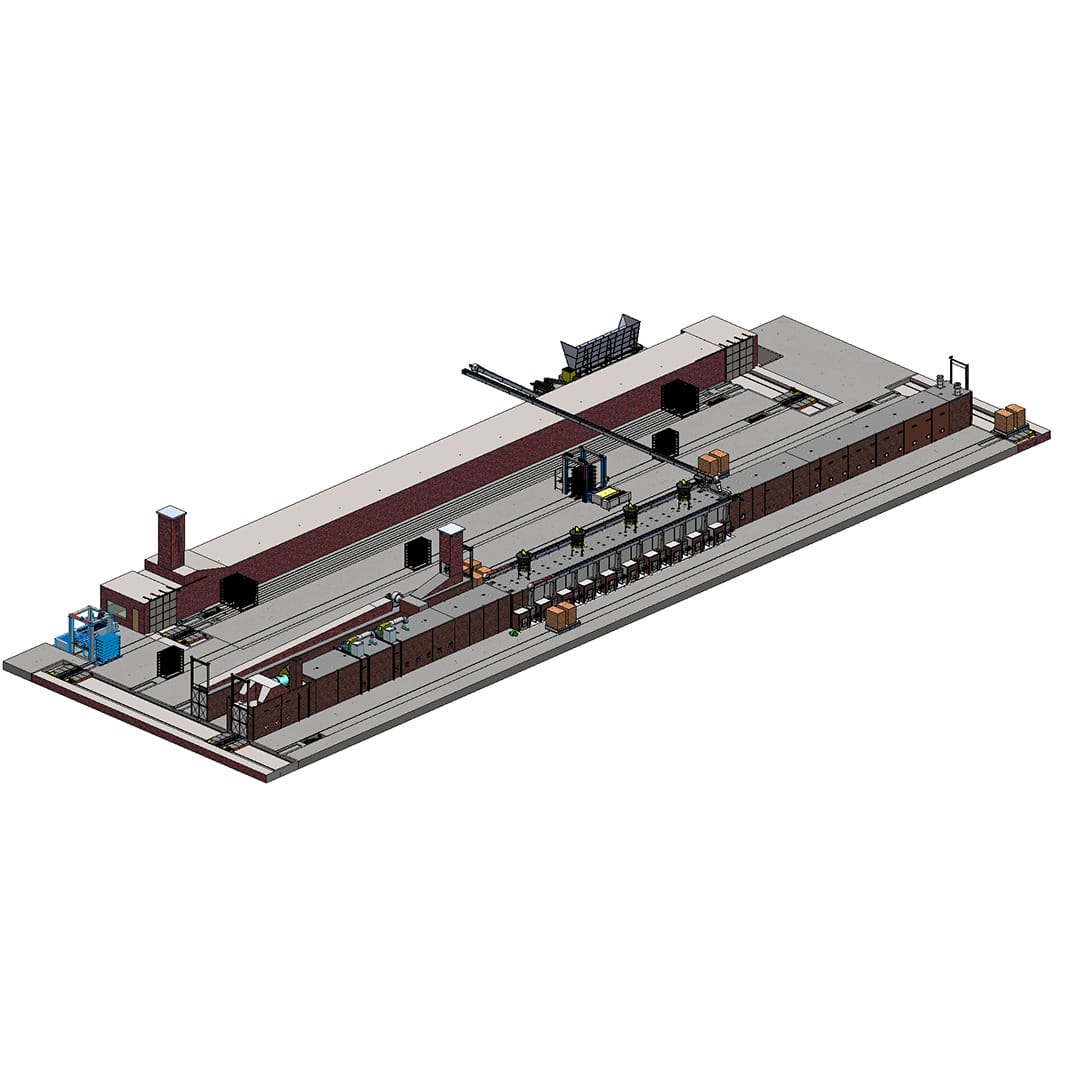

- Models with capacity between 120 and 500 tons of burned material per day;

- Homogeneous burning of all products;

- Reduction in labor for operation;

- Very low maintenance in the entire system;

- Improvement in the quality of burning of products;

- Simplified, clean operation in an organized environment.

Description

Play

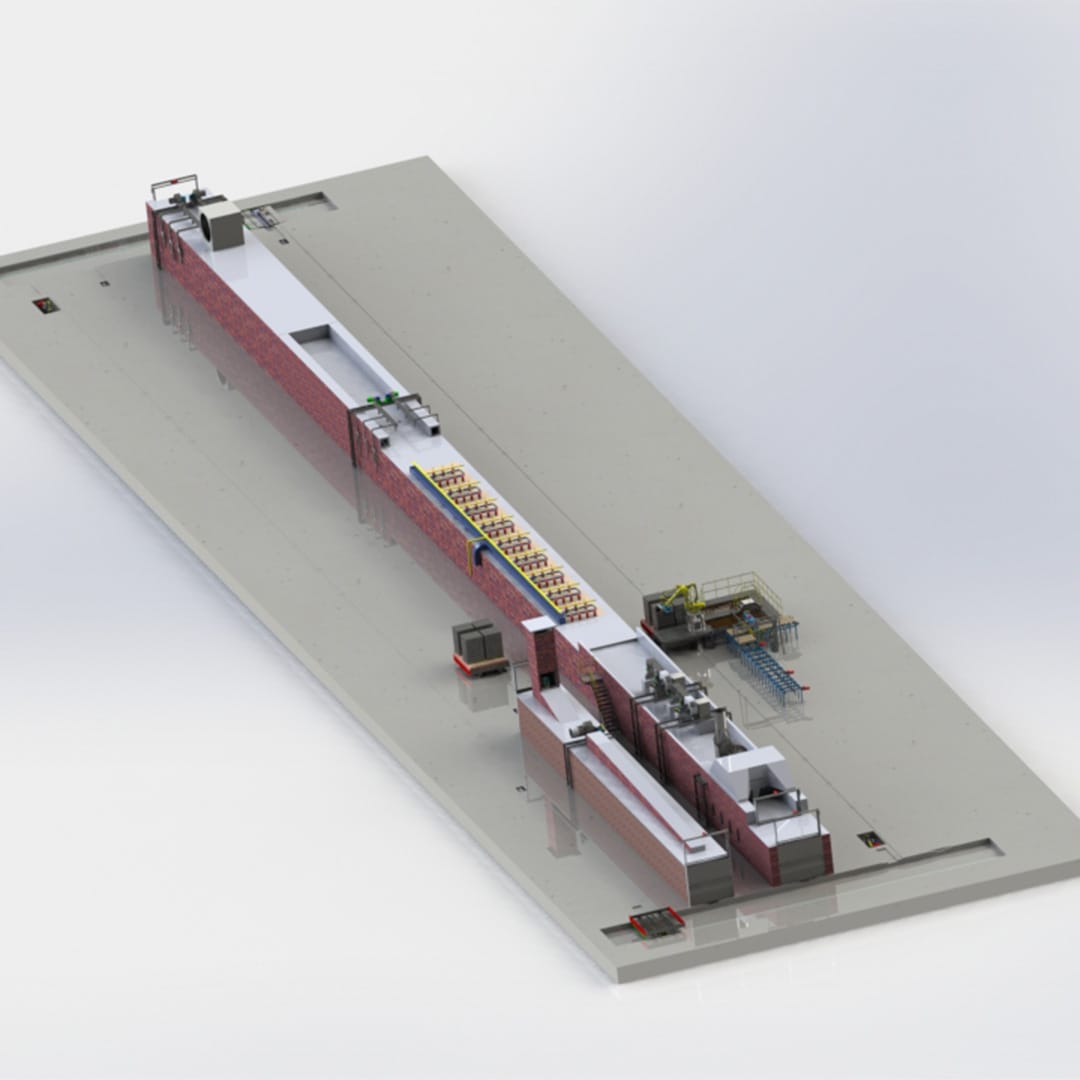

Our Tunnel Kiln was designed to meet the needs of ceramics companies that want to perform high-quality firing in a fully automated manner.

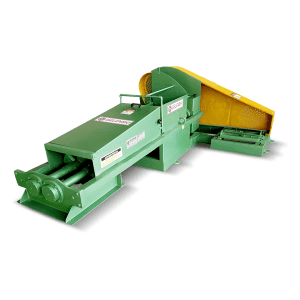

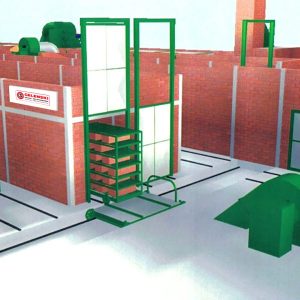

It works in conjunction with our Automation, Tongs, Robot and Dryers, ensuring complete automation of the entire firing and drying process, eliminating the need for labor, reducing costs and increasing the agility of your production!

It can be sized to your needs, and can be built in different sizes for different capacities and needs, ensuring a quality result with efficiency.