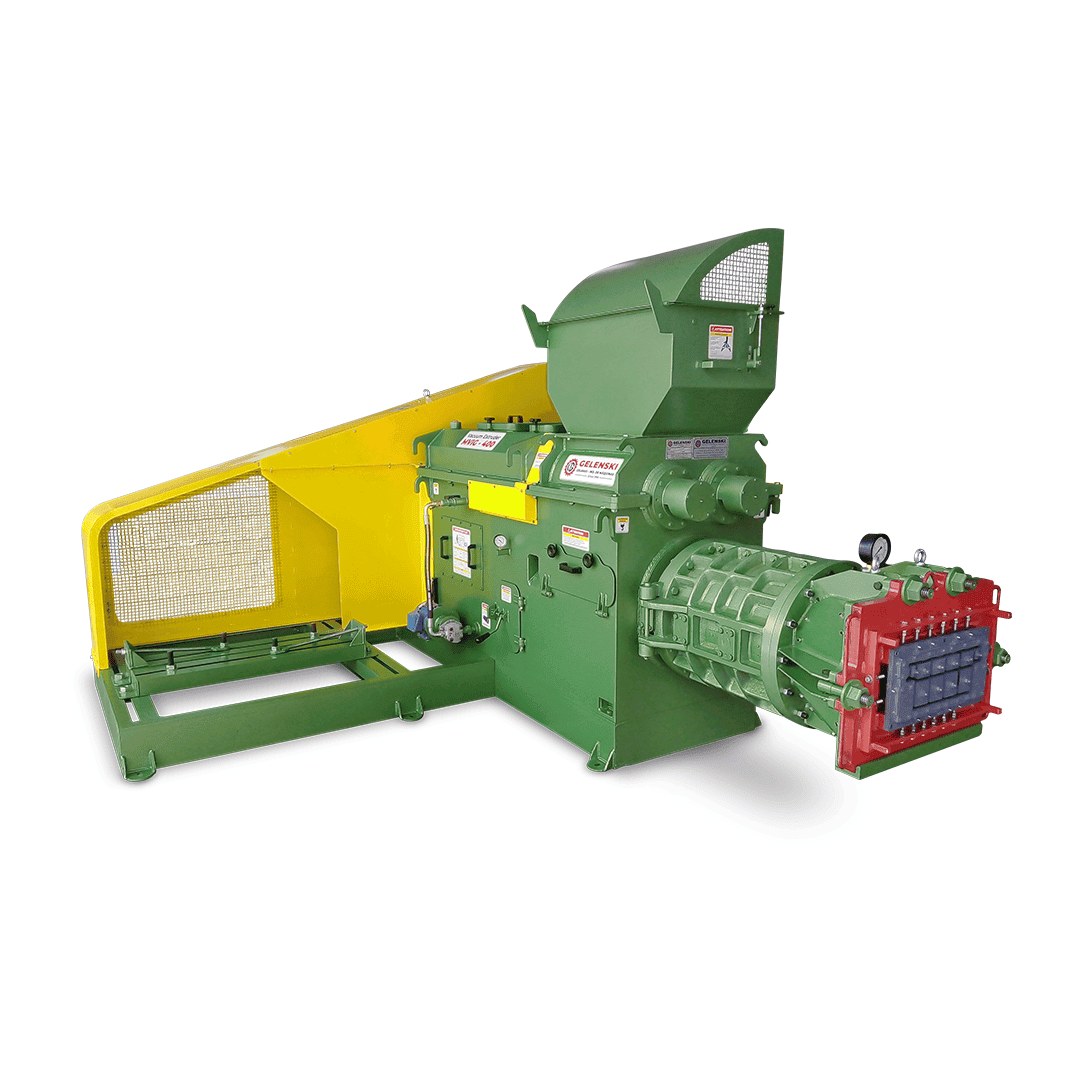

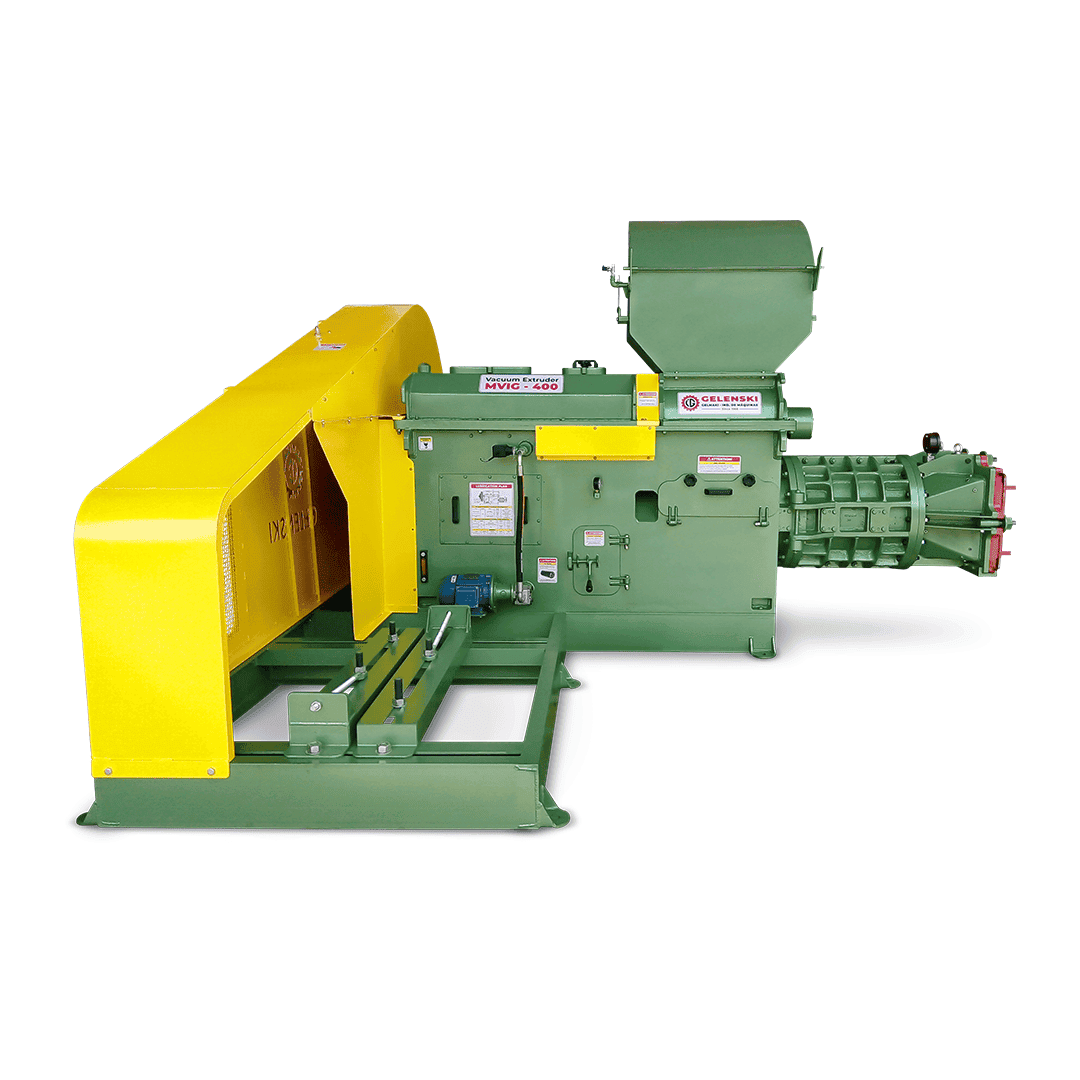

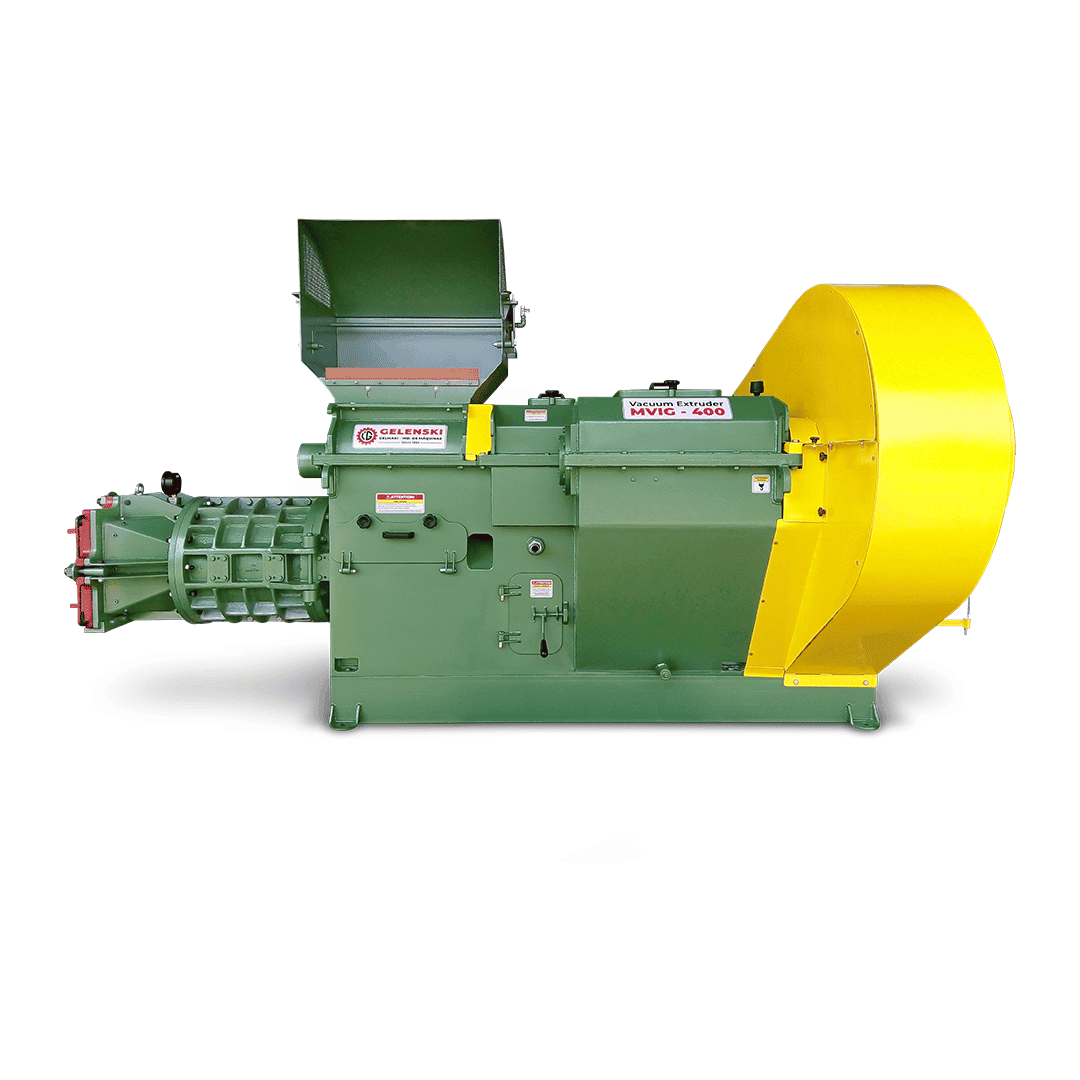

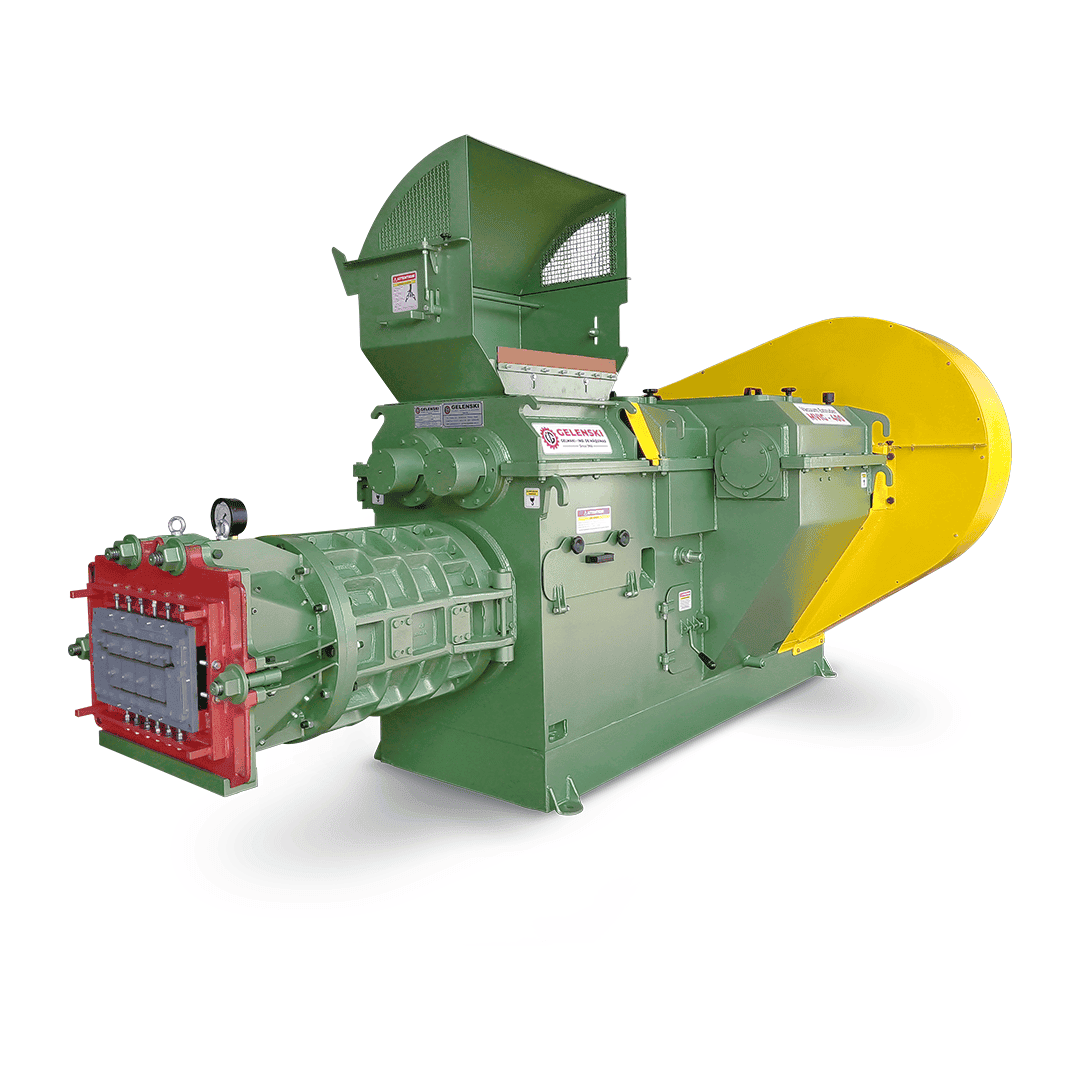

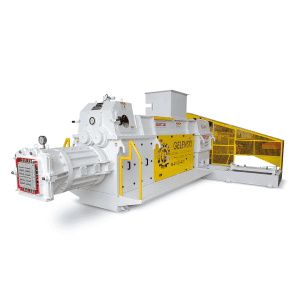

Vacuum Extruder MVIG – 400

- Production: 20 to 35 Ton/h

- Power: 125 to 150 HP – 4 Poles – 1780 to 1785 RPM

- Propeller Diameter: 400 mm

- Weight: 6,000 Kg

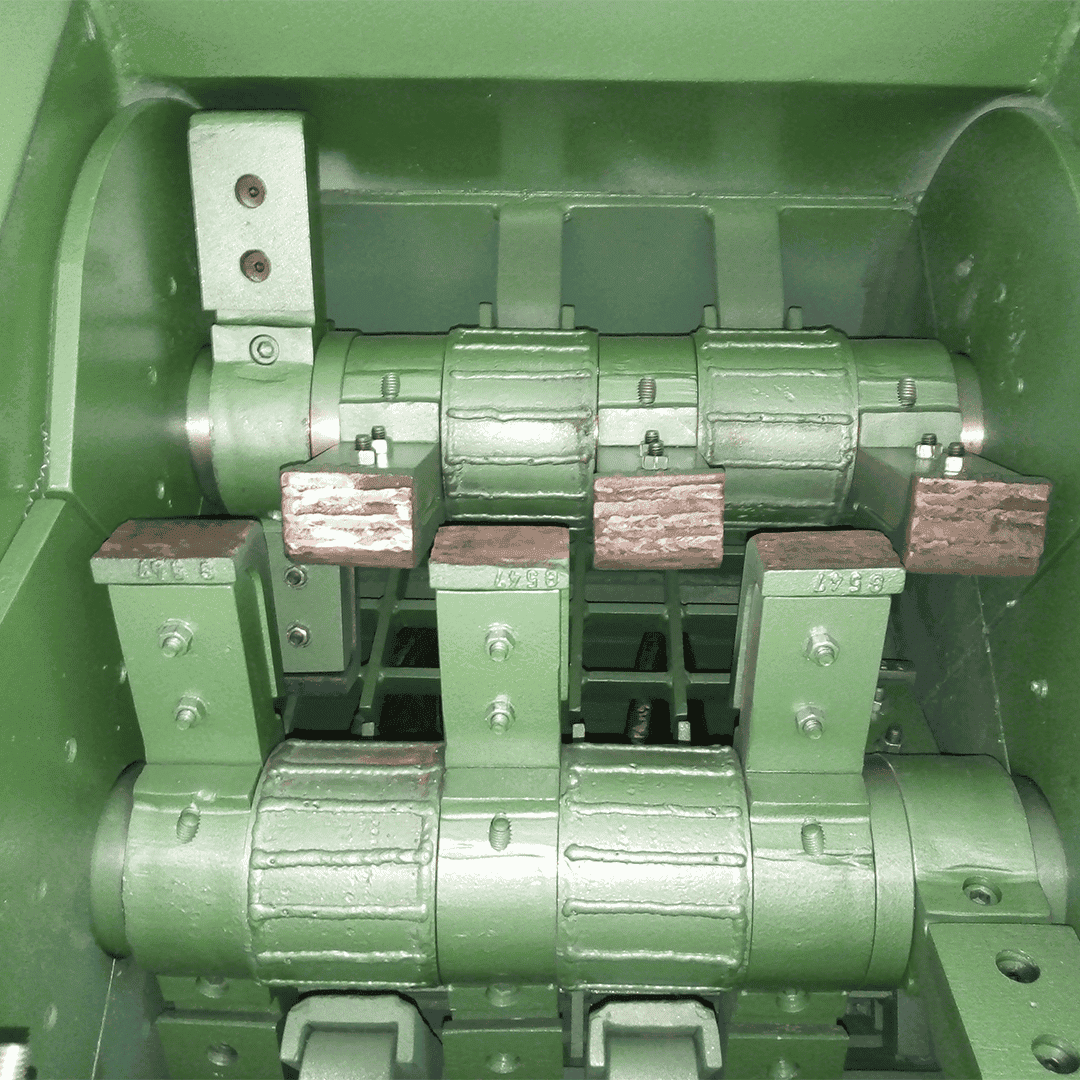

- Interchangeable parts for easy replacement.

- Manufactured with the best materials on the market, ensuring robustness and resistance.

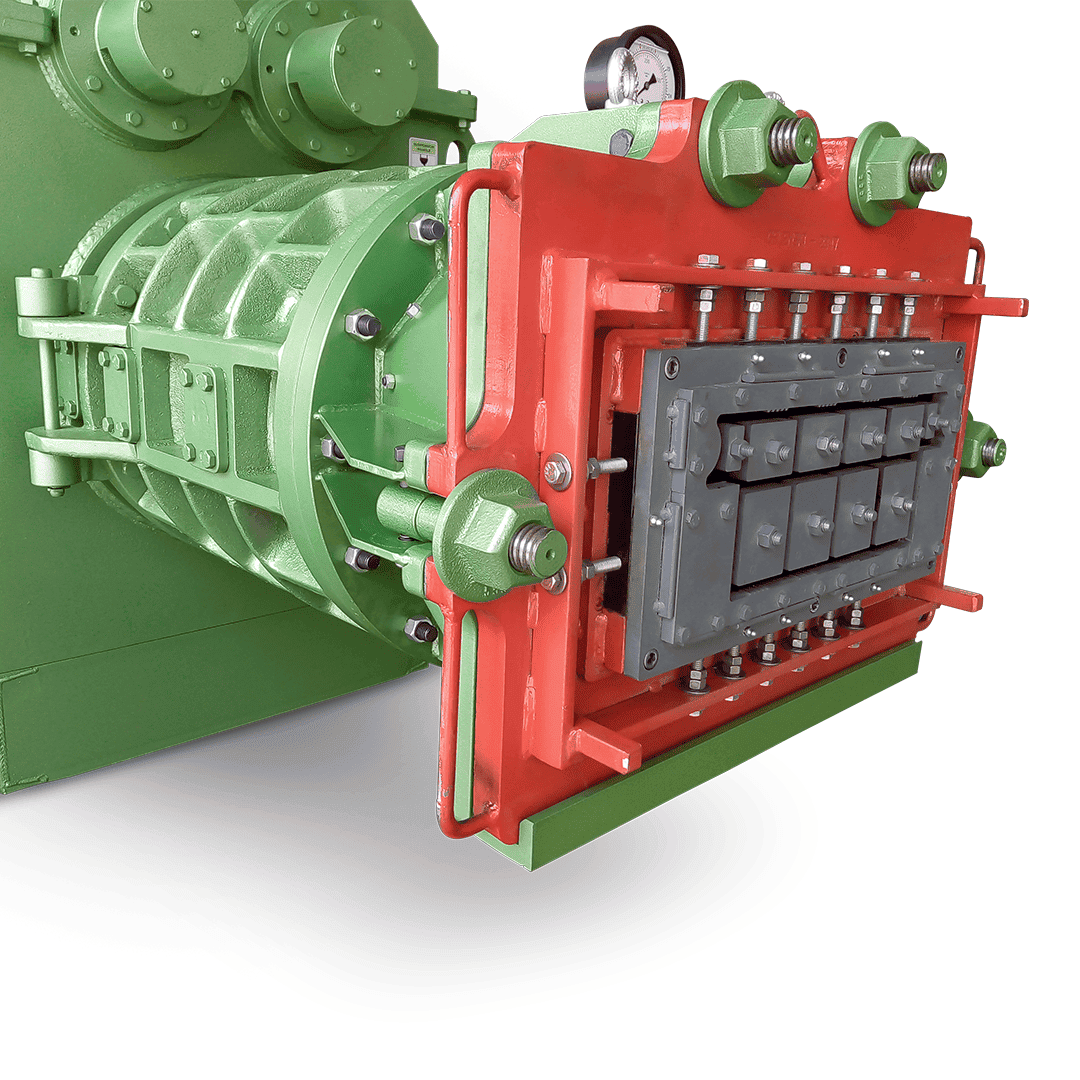

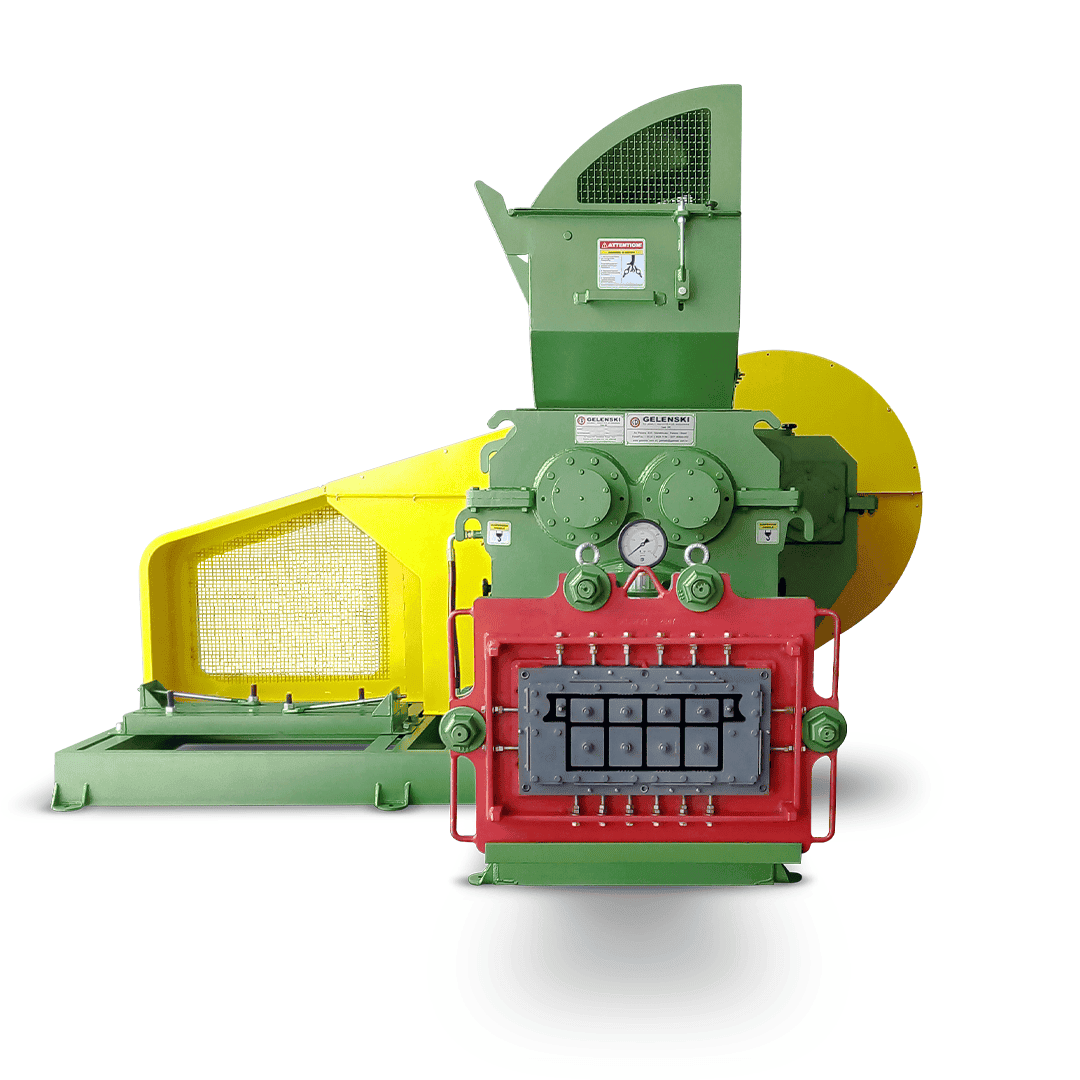

- Set of grids and vacuum chamber for better air extraction from the clay.

- Excellent extrusion performance, ensuring high quality for your product.

Description

The Vacuum Extruder, model MVIG – 400, is an excellent solution for improving the quality of your production, as it has an efficient and high-quality operating system that adapts to your needs. It allows the extrusion of various ceramic products, such as solid and perforated bricks, tiles, hollow elements, tile rods, among others.

Its vacuum system removes the air present in the clay before extrusion, which gives your product more quality. The clay then passes through the screw/propellers that compress the clay against the mold, carrying out the extrusion process in the desired shape.

The best and most resistant materials on the market are used for its manufacture, ensuring resistance and durability of the equipment.

Its casing is made of steel with structural reinforcements, internally it has linings with interchangeable parts that are easy to change and its mold can be adjusted to various types and sizes of extruded products.

Similar products

Related products

-

Bricks Loading & Unloading Robot

Read more -

Vacuum Extruder MVIG – 310

Read more -

Bricks Loading & Unloading Gripper

Read more -

Double Shaft Mixer MIG – 3000

Read more -

Static and Continuous Dryer

Read more -

Rolling Mill LIG – 800

Read more -

Vacuum Monoblock Extruder MAVIG – 400

Read more -

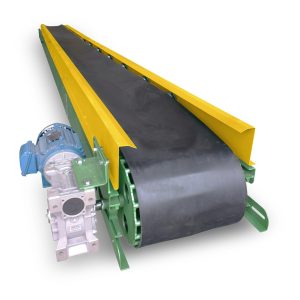

Conveyor Belt TMRIG – 15

Read more